Singer 152 class

Singer 152-11

Singer Class 152 Machines

There are two known versions of Singer 152- class machine, the 152-1 and the 152-11. These are machines of the 152- class (“152 dash class") and are not to be confused with Singer 152W class machines. 152W machines are lockstitch machines of an entirely different class.

For Facings, Stays, and Centers on Men's

Shirts

They were listed as for stitching facings and button stays and bluff shirt

centers on men's shirts and for general wide gauge double needle, double

chainstitch work in equivalent weight fabrics.

Double Needle. Four Thread Stitch type 401

This is a double needle, four thread machine producing two parallel rows of stitching. Each row of stitching is formed by one needle carrying an upper thread and one looper carrying an under thread, or lower thread. Each row of stitching formed is a Stitch Type 401, also called a 401 chainstitch, and also called a 401 double chainstitch, or more technically known as a "Federal Stitch Type 401".

Uniqueness and Desirability

I currently have a 152- class machine. It’s the only one I’ve ever come across

in person. There may have been a 152-1 machine on eBay in the past, or it may

have been another website. The 152-11 machine I have has a 1" gauge between

lines of stitching. It should be successful with button stays between 1 & 1/8"

up to 1 & 1/2". From my way of thinking, it's ideal for 1 & 1/4" wide stays.

I worked quite often for a factory that had several 147- machines sewing full

time, at full speed. I got to know and appreciate the 147- machines and by

extension the 62- machines as they have many of the same parts (same part

numbers) as far as I have seen.

The 148- machines are feed up the arm 147- class machines and the 152- machines

are wide gauge 147- class machines.

Quality of Stitch

Thankfully, as far as I have seen, Singer, Union Special, Wilcox & Gibbs,

Metropolitan, and all of the USA made, European made, Japanese made, and some

others too, have all been capable of producing a good-looking, well balanced

stitch. I feel that the Singer 147- class based machines produce perhaps the best looking

and best formed 401 chainstitch.

Use of term "Double Chainstitch"

Singer did use the designation 401 style stitch, and called a 401 stitch in most brochures a “double chainstitch”. I’ve never come across Singer using the

designation 401 style stitch for anything other than that same “double

chainstitch”.

Union Special " also used the designation 401 style stitch, and also called it

in many or most brochures a “double locked stitch”. They were the only maker

I’ve seen that used that term for the 401 type stitch. I’ve never come across

Union Special using the designation 401 style stitch for anything other than

that same “double locked stitch” terminology.

Upper thread take-up Variations

The 147- class machines had a particular design upper thread take-up that was

used in all early models of 147-, such as the 147-1, 147-2, etc., and was

continually used throughout all model years in certain models. A later design

upper thread take-up design was used in many of the later models such as the

147-80, 147-81, etc.

The 152-1 has the old style 147- upper thread take up, while the 152-11 has the

newer 147- style upper thread take up. They appear the same parts number wise,

The 152-11 also has the addition of ball bearing bed shaft support and balanced

shaft. The 152-11 added a choice of 9/16" gauge, while both had 3/4" through 1

& 1/2" gauge choices available at time of purchase. Of course, you

could purchase any kind or size of folder beyond these offerings through any of

the variety of attachment makers in the USA at the time.

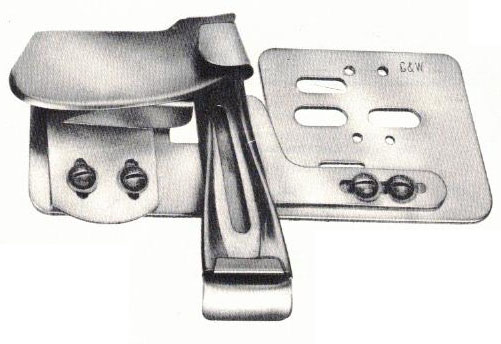

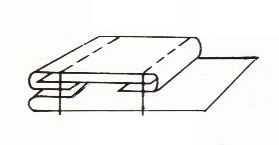

Bed Mounted Folders, Guides, and Attachments

button stay folder

button stay folder

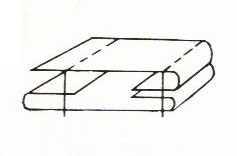

button

stay cross section

button

stay cross section

Any folders ordered with machine were listed in the brochures as being supplied

at additional charge. I’m guessing that these were originally made by Singer.

Then, at some later date, perhaps after 1948, were likely made by C&W Sewing

Machine Attachments Company. C&W was the brand of attachments that Singer

eventually offered if you weren't going custom folded at your choice of

attachment makers. The C&W catalogs proudly proffered that they were distributed

worldwide by The Singer Company!

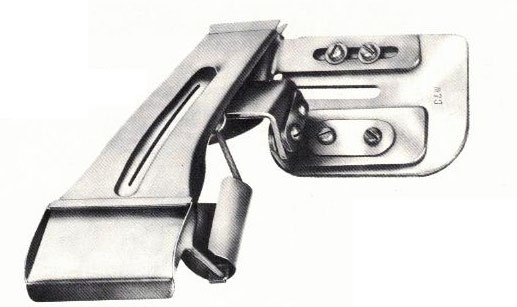

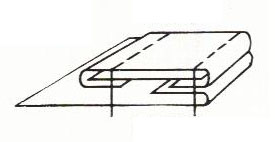

top center folder

top center folder

top

center folder for neck down sewing direction

top

center folder for neck down sewing direction

top

center folder for bottom up sewing direction

top

center folder for bottom up sewing direction

I believe C&W became, eventually, Tennessee Attachment Company.

Tennessee Attachment Company is in

business and still offer this full range of folders in each style and in each

width and with or without inserted linings and also variations including

material welt under facings and with or without cord inserted into welt while

sewing, etc. I believe that Atlanta

Attachment Co., and Linhart Sewing

Attachments (516-868-1558, 516-223-0261), among others, also all still

attachments in the USA of any type you need. Unfortunately, New York Sewing

Machine Attachment Co. does not seem to have an active website when I last

checked.

top center folder with welting inserted and optional cording

top center folder with welting inserted and optional cording

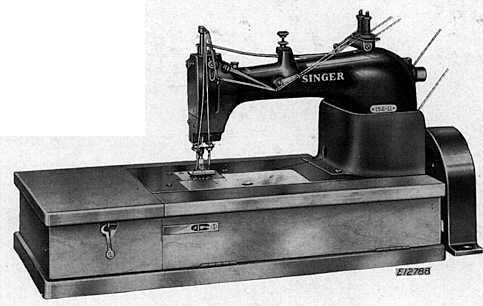

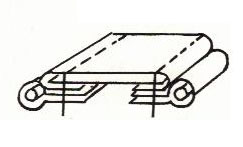

Machine Mounting to Table Top

All 147- class machines and the 152-1 and 152-11 machines came with a "bench

stand" with the machine head as the standard setup. This allowed setting the

machine base on the table top. A cast iron pan (with a drain hole) was affixed

directly to the table top. The machine sat on this and a wooden work surface

with hinged sides was installed around the machine work plate. To me this was

perhaps the least desirable mounting although it has a classic, perhaps, 1800's

look to it.

You could order two additional types of mounting at additional cost. The "semi-submerged" and the

"fully-submerged". The 152-1 was set semi-submerged on a wooden plank, similar

to what you see with many Union Special and Wilcox & Gibbs machines. The 152-11

was set upon a formed and cast semi-submerged base. The 152-1 was set fully

submerged also on a wooden plank, also similar to what you see with many Union

Special and Wilcox & Gibbs machines. The 152-11 was set upon a formed and cast

fully submerged base.

The 152-11 style semi-submerged had a cast steel base that sat under a machine

cutout. This had the machine closer to the table top surface. A wooden works was

placed around the part of the machine work plate that sat above the table.

Unlike the standard bench stand, the woodwork for the semi-submerged mounting

was fully rounded and smooth and was more substantial and covered a broader area

of the table top. The woodwork was hinged and as the machine was only

semi-submerged, you could instantly flip the hinged wood aside and have full

access to all adjustment screws. Hard to find but when I could find this

arrangement I bought it!

The 152-11 style fully-submerged had a cast steel base that sat deep so that the

machine work plate was flush with the table top surface. No woodwork needed and

the work surface was the table surface. This is nice especially for fast runs,

but the machine had to come up out of the cutout for adjustments. Not my

favorite arrangement for a service person, unless the front of the table top was

made hinged and swung out of the way. I've not seen this hinged top on these

Singer 152- class machines.

Brochure from February 1954

Brochure from May 1937